| Difficulty: | Number: | Miles: | Altitude: | Obstacles: | Time: |

|---|---|---|---|---|---|

| Easy 3 | CR 52 | 2.60 | 9,570 to 11,200 ft. | NA | 1-2 hours |

BLM, Tres Rios Field Office

29211 Highway 184, Dolores, Colorado 81323

(970)882-7296

Closure:

July - Best

August - Best

September - Best

October - Early snows possible

Accessed:

In May of 1871 a second group of prospectors made their way into the Animas River valley and camped at Cunningham Gulch. They relocated previous claims, and conducted additional prospecting. The party also made the short climb into Mason Gulch and began blasting ore from the Little Giant vein. Because there was no way to transport the ore out of the San Juans to be processed, the group decided to process the ore on site using a system based on the traditional Spanish arrastra. This simple apparatus consisted of a circular stone floor hemmed in by low sidewalls with a capstan at center and a beam that rotated around the capstan. A draft animal walked a track around the arrastra and pulled the beam, which dragged stones around the floor. As the stones ground the ore, water and mercury were added, which amalgamated with the gold as it was freed. The Little Giant facility featured four drag beams linked to a side-shot waterwheel with a leather belt to connect the system together. The arrastra was relatively large at 15 feet in diameter, the sidewalls consisted of vertical planks, and the waterwheel was 18 feet in diameter. In order to use waterpower, the arrastra was built on the valley floor of what came to be known as Arrastra Gulch (Mason Gulch). Once completed a trial run of ore was processed. After the ore had been ground, the standing water was drained, the sandy tailings were removed leaving a dark gray amalgam lining the stone floor. The miners scraped the material into a leather bag, squeezed out the liquid mercury, and heated the pasty mass in a retort to drive off and condense the remaining mercury for reuse. When the retort's cover was removed, they were greeted with gold. They had produced the first pure gold in the San Juans.

In July of 1873, with investor backing, the arrastra for the Little Giant mine was replaced by a mill which included a Dodge Crusher to pulverize crude ore into small cobbles, a battery of stamps to reduce the material to sand and gravel, and a ball mill to pulverize the remains into a slurry for separation. With 500 vertical feet separating the mine from the mill a single line tram was built to connect the two. This was the first tram system and processing mill in Arrastra Gulch.

In 1874 prospectors bagan searching inaccessible areas in Arrastra Gulch. Two prospectors explored the gulch's shear, west wall and found an exposed vein, nearly opposite the Little Giant Mine on the east side of the gulch. One of them claimed it as the Gray Eagle mine. The vein cropped out high on the cliff face, so the prospectors had to scale the wall to determine the vein's orientation, and place corner monuments. They produced and shipped 1,200 pounds of high-grade ore and sent it to New York for processing. By the end of the 1874 season the Little Giant vein had run out and could not be relocated, so the mill work slowed and then the mill finally shut down without the Little Giant gold ore.

In 1876 prospectors began looking to the more isolated areas around Arrastra Gulch and finally made the climb into the basin above the sheer headwall of Arrastra Gulch. John Reed was the first prospector documented to scout a route up the headwall. What he found was another hanging valley carved by glaciers. At the valley's center lay a pristine glacial lake. Examining the flank of Round Mountain on the valley's west side, Reed quickly found more than one vein that carried silver and industrial metals. He made two claimes on Round Mountain, the Whale and the Round Mountain, and located the Silver Lake vein near the glacial lake. Around the same time, another prospector working at the valley's head identified a huge fault featuring a vein he claimed as the Buckeye. When the prospectors returned the following year, Silver Lake Basin, as the valley came to be known, saw its first production, which was shipped by burro to the Greene Smelter near Silverton. The Gray Eagle mine was also producing and shipping ore to the Greene Smelter

In 1881, several prospectors imitated John Reed and made the dangerous ascent into the Silver Lake basin, where they prospected south of Reed's claim. They found a rich vein, naming two claims the Iowa and Stag, and began development of a tunnel and shaft. At the end of the season, the party had ore samples assayed in Silverton. The report found that the ore was not only rich with silver and industrial metals, but also gold. In 1882, the party returned and began production. During 1880 and 1881, John Reed traced the Silver Lake vein for a considerable distance with shallow excavations hewed into solid bedrock. In 1882, he produced several tons of ore from a tunnel he drove. During a stay in Silverton in 1883, Reed convinced John W. Collins that the Silver Lake and Round Mountain claims would pay well if worked, but it would required an initial investment. Collins and Reed formed a partnership, ascended into the basin, with lumber and equipment to build a blacksmith shop and cabin, and began production.

Benjamin W. Thayer and James H. Robin examined the Iowa Mine in 1888 and found a vein that offered an unusual combination of gold and silver. The partners leased the property in 1889, began production, and were elated when the Sherman act restored silver's value making the new ore even more valuable. Thayer and Robin increased the workforce to expedite development and discovered a second vein of galena. During the summer of 1891, at the Iowa Mine, work began to repair the buildings up on Kendall Peak's cliff and additional supplies were brought in so a small crew of miners could stay the winter. After the mine became snowbound, the miners developed several veins and stockpiled the ore for the coming thaw. In June the thaw arrived, the precious payrock was packed out, and reports were that the veins looked better than ever. Thayer and Robin realized that their meager investments would constrain future production. More money was necessary for the mine to blossom. Robin approached Gustavus and Edward Stoiber, owners of a sampling works. The men organized the Iowa Gold Mining & Milling Company.

|

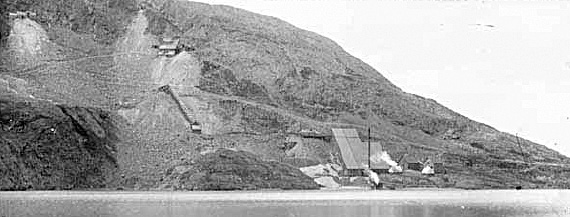

Upper Silver Lake mill in 1890 |

|---|

After a diagreement the Stoiber brothers split their assests, and Edward took over running the Silver Lake Mine while Gustavus ran the sampling works. Edward spent two years sampling ore, examining the property's geological features, conducting assays, staking claims, and calculating the most effective manner of development. Unlike most mine owners, Edward took a primary interest in the low-grade ore and considered high-grade material to be merely a bonus. The main problem, however, was that the costs of shipping the low-grade payrock from the basin and processing it in the sampling works exceeded the returns. Stoiber's plan was to mine ore in large volumes and concetrate it with highly efficient systems, which would make the low grade ore profitable. By 1890 he had a plan devised. During the late spring a small army of workers with mule trains packed in thousands of board feet of lumber, tons of hardware and machinery, and the basic necessities of life. They assembled the largest surface plant and mill yet in the county. When finished, the mill was able to generate 50 tons of concentrates per day, which provided Stoiber his economy of scale. Because there was no storage facility for the hundreds of tons of concentrates and high-grade ore that Stoiber expected to produce, he built his own. Stoiber chose the abandoned Little Dutch Smelter site on the west side of Arrastra Gulch's mouth. The crown jewel to Stoiber's instant empire was an electric power plant that he commissioned on the Animas River next to the storage facility.

In 1890, electricity was a revolutionary technology under experimentation, and the San Juans served as a cradle for its application to mining. In 1888, the Virginius and Tomboy mines above Telluride installed the first AC electric plants in the San Juans, followed by John Terry's small DC electric facility at the Sunnyside Mill in Eureka Gulch. Stoiber was not far behind. He completed the second AC power plant in the San Juans, and Colorado. The power plant was built on the Animas River, and power lines carried the electricity two miles up to Silver Lake Basin, which lit the interiors of the buildings and ran several small motors in the mill. At the beginning of November 1890, Stoiber started the mill and it ran to perfection. After two years of constant production and milling, Stoiber declared the Silver Lake a success. A second boardinghouse was built at the mine and the work force increased to 130. Like the first boardinghouse, it featured luxurious amenities such as running water and steam radiators.

To improve the Silver Lake mine's output, Stoiber and the expert metallurgist Robert J. McCartney worked on improving the concentration equipment. They invented one of the best vibrating tables for concentrating San Juan ores, the so-called Stoiber-McCartney table. The electricity that was generated by the small power plant was used for lighting and to run simple appliances. Motor technology had not been developed yet so steam powered the energy-intensive machinery. This kept a herd of mules busy packing the fuel coal up Arrastra Gulch to the mine. To reduce expenses, Edward Stoiber installed more motors at the mine and mill in 1894 and built a second power plant on the Animas River, which also provided electricity to his brother's Iowa Mine. He chose a site on the south side between Arrastra Gulch and Silverton for the new power plant, which had a generator house, boiler house, a set of massive coal bins, and direct rail service. In 1895 he also erected what was the largest and best appointed residences in the San Juans with hot and cold water, sinks, bathtubs, toilets, and steam heat. Edward and Lena Stoiber named the power plant and mansion complex Waldheim, German for forest home.

|

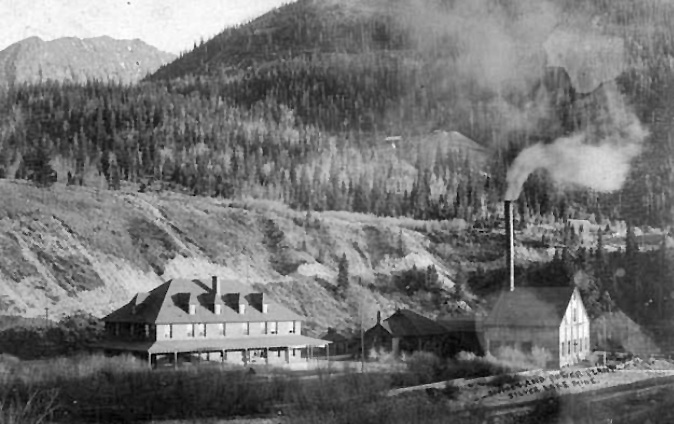

Waldheim and power plant in 1895 |

|---|

In 1895 Stoiber wanted to improve his operation while minimizing his debt. One of the large expenses was the mule teams needed to haul ore down and supplies up to the Silver Lake Mine. To lower costs Edward planned on building a tramway. He designed the system in two segments that linked the mill with the shipping terminal on the Animas River. Stoiber contracted with William M. Frey, tramway expert from Leadville, to build the first 8,700 feet. By November of 1895 the first segment of the tramway was operational. In 1898 William Frey began construction on the tramway's second segment and on a massive terminal that replaced the original. In addition to receiving ore, the terminal served as a base station for the mine and included assay, machine, and carpentry shops. In total, the ore bins had the capacity for 16,000 tons of material, and the two tramway segments totaled almost 15,000 feet, making it one of the longest systems in the state.

Gustavus Stoiber and James Robin were also busy improving the Iowa Mine. The Iowa was second only to the Silver Lake in terms of implementing economies of scale. They also focused on largescale production and savings, including improvements at the mine, widespread adoption of mechanization, a mill, and a tramway. In 1895 Gustavus and James constructed a large concentration mill, the Iowa Mill, to separate out the waste rock from the ore, on the floor of Arrastra Gulch, almost directly over the obsolete Little Giant arrastra. This location was inefficient in the beginning because it required mule trains to carry down the crude ore, but the location made shipping out the concentrates easier. The next step was to build a tramway that would remove the need for the mule trains. They contracted with the Trenton Iron Works of New Jersey for a Bleichert tram system. In 1896, Gustavus, Robin, and the other Iowa investors were well on their way to building an empire as large as Edward's Silver Lake. At this time they purchased the Tiger Mining & Milling Company, which just began work on the Royal Tiger Mine directly across Silver Lake from the Iowa. The outfit had done little with the property and was eager to sell because they did not have the capital to develop the mine. Edward used his power plant to provide electricity to both the Silver Lake and the Iowa Mines. Gustavus had installed one of the largest compressed air systems in the county at the Iowa and provided air for drilling in Iowa and also the Silver Lake. Edward housed most of the combined workforce at the Silver Lake boarding houses.

At this time a very ambitous venture was started by Gustavus, Robin, Joseph Bordeleau, Frank B. Brown, and R.S. Courtney. They organized the Silverton Deep Mining & Tunnel Company to drive a haulage tunnel from Arrastra Gulch to undercut the Silver Lake, Iowa, and Titusville mines. In the spring, miners began the Unity Tunnel high up on the west side of Arrastra Gulch.

Compressed air rock drills were used at this time. To increase the number of drills employed at the Silver Lake Mine, Edward was going to have to haul up a new air compressor. To save this cost he experimented with electric drills. By 1899 his miners were using the new drill technology successfully to increase production.

|

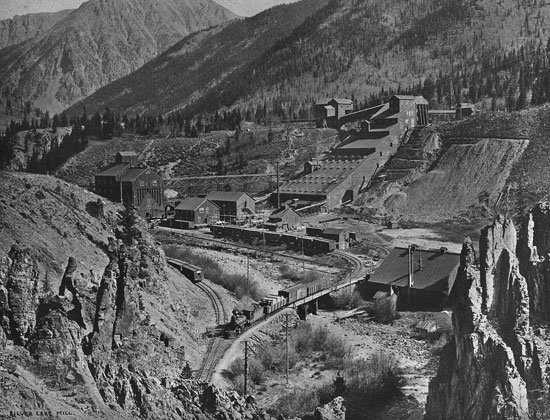

Upper Silver Lake mill in 1898 |

|---|

|

Iowa mine in 1898 |

|---|

In 1900, Edward, with McCartney's assistance, built the Silver Lake Mill on the Animas River. The mill and associated facilities were among the largest and most advanced ore treatment complexes in the San Juans, if not Colorado. The mill was able to treat an astounding 1,000 tons of ore every 24 hours, more ore than many mines generated in a month.

|

Silver Lake complex on the right. Iowa complex on the left. |

|---|

While the Iowa Mine was not quite as extravagant as the Silver Lake, Gustavus Stoiber and James Robin were almost matching Edward's improvements one-for-one. In 1898 an aerial tramway form the Royal Tiger Mine to the Iowa Mine was built and a compressed air line was also run. The double-rope tramway allowed miners at the Royal Tiger to send ore over the lake and into the Iowa terminal, where workers coupled the buckets onto the main line. The buckets then coasted down to the Iowa Mill, were emptied by workers, and sent back up to the Royal Tiger for filling. In 1899 Gustavus and Robin also built a sotrage facility for the mines ore on the north side of the Animas River. A tramway ran from the Iowa Mill in Arrastra Gulch to the storage facility where the Silverton Northern Railroad line could haul the concentrate out. In 1898, Edward installed a mechanized surface plant at the Unity Tunnel that included an aerial tramway tied into the Silver Lake system. Edward provided the Unity crew with plumbing, steam heat, and electric lighting. In 1901, miners made the connection with the deepest workings in the Silver Lake Mine, which were 3,000 feet to the south of the tunnel entrance. In 1901, Edward Stoiber's Silver Lake empire was purchased by the Guggenheims for $2.5 million. Edward and Lena retired to Denver and traveled Europe after the purchase.

The Guggenheims continued Edward's operation. They purchased the Titusville and the Scranton City because these mines lay long the same geological features as the Silver Lake workings. The miners produced 260 tons of ore per day, and although this was only one quarter of the new mill's capacity, it still was more than any other mine in the county. Around 30 percent of the ore flowed out of the Unity Tunnel, which was now a haulageway for the Silver Lake's lower workings, and the remainder came from Silver Lake Basin. With all the ore descending to the new Silver Lake Mill, the old mill at Silver Lake Basin was abandoned, only the boarding house and maintenance buildings were used.

|

Lower Silver Lake mill in 1903 |

|---|

In 1903, the Guggenheims merged with smelting giant ASARCo, which controlled the Silver Lake empire both for the mine's profitability and as a source of ore for the Durango Smelter. In October 1904, workers in the tramway's turning station above the Iowa Mill stoked their stove a little too high, and the wind blew sparks out of the stovepipe onto the building, which caught fire and burned to the ground. The cables on both tram segments released, which dropped the tram buckets and pulled over a number of towers. The system was a total wreck and the conflagration suspended the entire mining operation. The Silver Lake Mill was shut down until the tram system could be repaired, and instead of bringing the original mill in Silver Lake Basin back into operation, the manager laid off half the workforce and curtailed activity at the mine.

After the tramway had been repaired, another catastrophe struck. In 1906, workers at the Silver Lake Mill on the Animas River noticed that a fire had been deliberately started in the office and sounded the alarm. They frantically rushed to the hydrants only to find that someone had cut the hoses. With no way to control the fire, the blaze enveloped the entire building, ancillary structures, and the lower terminal for the tramway, which suffered another massive release. The devastation was not total because the ore elevators, powerhouse, shops, and boardinghouse remained intact. Without a mill, ASARCo suspended operations yet again and considered whether the Silver Lake was worth the trouble.

ASARCo decided to invest in the Silver Lake one more time. A new mill was built on the site of the burned out Silver Lake Mill that had two flow paths, one for the Silver Lake Mine ores and one for the Aspen Tunnel ore that was low grade with a high zinc content. By April 1907, the reincarnated Silver Lake Mill was finished and featured the split flow paths as planned. The path for Silver Lake ore could treat 200 tons per day and the other path 100 tons, a large downgrade from Stoiber's original design of 1,000 tons per day.

The Iowa Gold Mining & Milling Company, the second largest outfit in the Las Animas district, also experienced problems during the early 1900s even worse than the Silver Lake. By 1901, the Iowa showed signs of exhausting its ore after only six years of intensive mining. To improve profitability an aggressive exploration and development campaign was started to find more veins. When this failed, the owners curtailed operations, let go more than half of the workforce, and suspended the mill and tramway. Gustavus and Robin then took the option that companies reserved for times of trouble and leased both the Iowa and Royal Tiger properties while seeking a buyer. In 1902, Al Kunkle struck a fabulous vein in his Royal Tiger lease, but it lasted for only one year. Even the Guggenheims, who owned the Silver Lake on one side of the Iowa and the Titusville on the other were not interested in purchasing the mine. Depressed and despondent, Robin shot himself in 1903. In 1905, an avalanche wrecked a significant portion of the Iowa Mill. Gustavus died of a massive stroke on the train from the Red Mountain district down to Silverton soon after.

The Garfield Smelting Company, a subsidiary of ASARCo, reopened the Aspen Mine, a short distance west of the Silver Lake Mill, and was confident enough in the operation to build a new tramway. Unfortunately neither treatment path in the new mill recovered a sufficient percentage of the valuable metals being sought. ASARCo cancelled production at the Silver Lake and leased out blocks of ground instead of working the mine itself. Garfield decided to continue with its Aspen project and erected its own mill at the tunnel. Garfield had no luck with the Aspen ore either and suspended work at the Aspen as well. With an enormous amount of capital invested in both the Silver Lake mine and mill, ASARCo went back to the drawing board to refit the facility. By late winter of 1909, ASARCo was ready to try again, brought ore down from the Silver Lake and over from the Aspen, and ran the first tests. To the relief of all, the mill ran as expected. Management prepared to resume normal operations at the Silver Lake Mine, but before they started, the tramway's turning station burned. Yet another disaster struck when a series of avalanches let go after a powerful spring storm in 1911. One slide took out towers for both the Silver Lake and Iowa tramways. The last and final disaster for ASARCo struck in the summer of 1912. A fire occurred on June 30 at the Silver Lake Mine, and practically all the mine buildings were destroyed, except the boardinghouse, which was saved by dynamiting smaller buildings between it and the blacksmith shop, where the fire started. The upper terminal of the tramway was destroyed, necessitating the closing of the mill. With that, the company finally gave up on the mine and leased out blocks of ground to small parties.

The heirs that inherited the Iowa and Royal Tiger mines assumed that both mines were played out. Otto Mears suspected otherwise and in 1908, Mears and Jack Slattery approached the Iowa owners with a proposal to lease the entire idle operation. The owners accepted, and Mears and Slattery organized both the Iowa-Tiger Leasing Company and the Mellville Leasing Company. During the summer, Mears and Slattery rehabilitated the surface plant and underground workings at both the Royal Tiger and Iowa, and then pursued an organized exploration program for ore. Contrary to the property owners' misconception, the miners found plenty of low-grade material available in the old stopes and began production. One of the groups working the mine realized that the original Iowa company paid little attention to the geology below the main tunnel level and assumed that ore surely lay deep in the ground. In 1909, miners sank a shaft and discovered an extension of the Melville Vein, which had been previously mined in the upper levels. The Melville vein yielded for years. Elsewhere in the workings, another crew discovered an entire vein of ore valued at $1,200 per ton. In 1910, Louis Quanstrom, the metallurgist in the Iowa Mill, noticed that the proportion of gold recovered from Royal Tiger ore constantly increased and suspected that the miners must have been encountering gold stringers too fine to be obvious. Quanstrom relayed this to the Royal Tiger foreman, who tested the idea by blasting a chamber out of the vein's hanging wall. To everyone's surprise, the shot revealed a hidden, parallel gold vein. Heavy production continued through 1913, and after five years of continuous yield, Mears and Slattery finally saw operations at the Iowa and Royal Tiger slow.

Louis O. Bastian introduced a technological development that revolutionized the definition of profitable ore. In 1914, Bastian installed the county's first flotation machines in the Gold King Mill. Flotation relied on oil or detergent to float metalliferous material away from finely pulverized ore in rectangular cells or tanks. Mechanical sweeps or paddles shoved the metal-rich froth out of the cells and into troughs that carried the material to other processes. Mining companies scrambled to find the capital for flotation in their mills, and 1915 saw a wave of installations. Bastian refitted the North Star and Iowa mills. Widespread utilization increased through 1916. By 1917, flotation began to deliver on its promise of improved ore concentration. It separate the valuable metal from ore that was difficult to process and it made low grade ore profitable to process. Mining companies revisited previously ignored veins, reopened old workings, and recovered huge volumes of low-grade material cast off as waste.

After approximately twenty-five years of continuous, heavy production, Silver Lake Basin remained one of the most important centers in the county. Mears and Slattery continued leasing the Iowa Mine and sent the ore down to the Iowa Mill via tramway. They also leased the idle Silver Lake Mine from ASARCo and rehabilitated the Stoiber Tunnel. In 1917, experienced miners noticed an eight-foot-wide vein in the walls of the Stoiber Tunnel. The vein's copper, silver, and gold content were a boon to Mears and partners. The Unity Tunnel was also worked by lessees who pooled their capital and modified the idle Bleichert tramway at the Unity so that it terminated near the Iowa Mill, where the lessees sent their ore. The Iowa Mill was the center for production in and around Silver Lake Basin. Even with the installed flotation equipment, done in 1915, the mill workers had a difficult time keeping up with the ore flowing in from all directions.

The Mayflower, located amid the cliffs forming the east wall of Arrastra Gulch, develped late in the San Juan mining history. As early as 1913, G.H. Malchus scraped together enough capital to develop the property, begin production, and build a Bleichert tramway from the lower tunnel down to a terminal adjacent to the Iowa Mill. While the distance to the mill was very short, the steep, loose scree slopes made a reliable road impossible. Malchus hired a crew to lengthen the development workings. In 1915, the American Oil Flotation Company leased the Silver Lake Mill from ASARCo with the intent of converting the plant for custom flotation. The custom business, however, was slow, and American Oil sought its own mine to provide a steady stream of ore. The Mayflower was the logical choice because it lay almost directly on the Silver Lake tram system. American Oil took an option on the property and paid Malchus $3,000 in earnest money, unfortunately, workers accidentally set fire to the surface plant shortly after. The Mears and Slattery syndicate moved in quickly as Malchus, ASARCo, and American Oil had collectively demonstrated that the Mayflower had the potential to become a significant producer. In 1916, the syndicate organized the Mayflower Leasing Company and developed enough ore for an excellent production run.

At the Mayflower, a crew of thirteen miners sent ore down to the Iowa Mill through 1918 and 1919 but were discharged the following year. The mine remained quiet until 1922, when Slattery, John F. Barnett, and Leonard L. Aiken organized the Mayflower Mining & Milling Company to work the property with a crew of only six. This operation only lasted a year. The Highland Mary Leasing Company kept the mine and mill producing through 1918 and developed several veins. Slattery suspended operations during the flu epidemic, and when he resumed, hired only ten workers in part because production declined. In 1920, Slattery found that the mill was not worth operating, shut the facility down, and did not renew the lease when it expired.

|

Mayflower mine |

|---|

At the Silver Lake Mine, Mears commissioned an unusual project involving the mill tailings dump that formed an artificial beach on the shore of Silver Lake. Ironically, Edward Stoiber was concerned enough with the water quality of the lake to install a sewer system for his boardinghouses, but flumed at least 500,000 tons of mill tailings from the original mill into the lake's north end. The thinking is that Stoiber did so to store the tailings for future reprocessing. The tailings were in essence a ready form of extremely low-grade ore with enough metal content to be profitable. The costly steps of crushing and grinding had already been done and the tailings only required advanced concentration. In 1913, Mears and Wilfley selected a mill site on the north side of the Animas River opposite the mouth of Arrastra Gulch. The system they devised for moving the tailings was unconventional. Special sand pumps mounted on a barge vacuumed up the tailings and piped them over to the outlet of Silver Lake, whose fall was increased by a low dam. The torrent carried the suspended particles over Arrastra Gulch's cliff headwall and down to the base, where another dam diverted the current into a large wooden drain box. Excess water flowed out of the box and the tailings reverted to a slurry, which flowed into a wooden flume that descended steeply along the gulch's west side. A trestle carried the flume out beyond the mouth of the gulch and over the river to the mill. As a concentration facility, the Mears-Wilfley Mill was completely novel. The interior was relatively level and featured only a handful of apparatus. The most imposing were grossly enlarged versions of Wilfley tables 12ft. wide and 48ft. long with two decks, and several twenty-four-deck shaking tables. Wilfley designed the contraptions to treat the tailings in economies of scale. The giant tables were for coarse particles, and the twenty-four-deck machines treated slurry of extremely fine material. According to design, the custom facility could treat 600 tons of Silver Lake tailings per day. The novel enterprise ran into trouble early in 1915. The flume developed a number of leaks because the tailings slurry acted like liquid sandpaper and wore the wood rapidly. Instead of lining the existing plank trough with sheet iron, Mears opted for concrete. More problematically, Wilfley's new machinery failed to perform as expected, despite the results of tests that suggested otherwise. Mears ultimately replaced the machinery with flotation. From 1915 through 1918, Mears' railroad hauled off dozens of rail cars of concentrates that fetched, in total over $100,000. The facility functioned smoothly into 1919 when Wilfley, in ill health, sold his interest to Mears. During the year, Mears closed the operation, having exhausted the richest and most debris-free tailings.

In 1937 or 1938, the Shenandoah-Dives Company started the Silver Lake Cross Cut as lower access to the Silver Lake Basin, it was intended to encounter the Silver Lake Vein first, followed by other mineralized formations. Miners bored the crosscut around the clock for several months before trouble swept the Shenandoah-Dives company. To reduce operating costs, concessions were demanded from the workforce, but the miners and mill workers were unwilling to concede. The parties came to a stalemate in 1939. In June the entire workforce struck and shut down the mine. The strike continued through the summer. Backed by investors with deep pockets, Chase waited out the workers fearful of losing their jobs. By the end of summer, the workers grew tired of their reduced union compensation and voted to return to work with no concessions. The union flexed its muscle, but Chase was now free to resume production on a greater scale then ever.

By 1940, Chase's miners finally reached the Silver Lake Vein after thousands of feet, and the vein not only featured ore, but some of the material was higher in grade than expected. Chase originally had a lease agreement with ASARCo, and when ASARCo realized just how much ore Chase found, the company became keenly interested in mining its own property. Adept at business as well as mining, Chase secured a reverse lease arrangement where ASARCo paid him to use the Mayflower Tunnel as a point of access for the Silver Lake ground. The contract provided the Shenandoah-Dives company with income for eight years.

Twitty, Eric Historic Mining Resouces of the San Juan County, Colorado United States Department of the Interior: OMB No.1024-0018, Print.

|

Ore bucket on Mayflower tram photo by: Adam M |

|---|

As you approach timberline the road will start to head up onto the east side of the valley wall. Shortly you will be above timberline with great views of the valley. At the lower part of the headwall of the valley you will come to a large switchback. From here the road use to be very challenging. Today the road is easily driven. Continue on the road past the switchback and you will continue climbing and eventually come to a second switchback.

|

Mayflower Mill tram tower photo by: Adam M |

|---|

From here the road heads straight up to a wide parking area at the old location of the Mayflower Mine tunne. You will pass tram towers and large avalanche barriers below the road. At the end of the road is a hiking trail that follows the old road bed that once went to Silver Lake. This hike is included in the track logs above.

|

Heading down from the Mayflower Mine parking area. Note the tram tower avalanche barrier. photo by: Adam M |

|---|

|

Road up to the Mayflower Mine - 1991 photo by: Adam M |

|---|

|

Mayflower Mine - 1991 photo by: Adam M |

|---|

|

Mayflower Mine - 1991 photo by: Adam M |

|---|

|

Heading down at the lower switchback photo by: Adam M |

|---|

|

Heading down through the lower section photo by: Adam M |

|---|

Return the way you came to get back to County Rd 2.

Silver Lake Hike

From the Mayflower Mine parking area there is a trail that climbs the Arrastra Gulch head wall. It follows what looks like an old wagon road. You will pass by some of the avalanche deflectors for missing tram towers as you work your way up switchbacks. When you get close to the top you will have to navigate a steep and wet rock outcropping to climb above a section of the old trail that has washed away. There is an old steel cable here to help you out if needed. Once above the rocky climb you will connect with the old trail again. You are now above the head wall. From here the hiking trail will cross the upper alpine landscape and follow Arrastra Creek to Silver Lake.

You will come to the lake at its north end, which gives you views of the remains of the Silver Lake Mill on the western shore first.

|

Silver Lake Mill remains photo by: Adam M |

|---|

|

Silver Lake Mill remains photo by: Adam M |

|---|

|

Iowa Mill remains photo by: Adam M |

|---|

|

Royal Tiger Mine remains photo by: Adam M |

|---|

|

Silver Lake Mill stamp banks photo by: Adam M |

|---|

|

Silver Lake Mill view from mine level photo by: Adam M |

|---|

You can continue around the west side of the lake to the Iowa Mill by following an old trail. It will pass some other small prospects.

|

Iowa Mill boilers and steam engines photo by: Adam M |

|---|

|

Iowa Mill boilers from the lake shore photo by: Adam M |

|---|